Sapci products - Accelerated concrete

Ready mixed concrete - Accelerated concrete

Description:

Climatic conditions have a very important influence on the quality of concrete. We must be concerned about it from its manufacture through its transport, and then its implementation.

As a general rule, when the temperature measured on the site is below -5 °C, placing concrete is not recommended.

Between -5 °C and + 5 °C, it can only be done with efficient means to prevent the damaging effects of cold.

Climatic conditions have a very important influence on the quality of concrete. We must be concerned about it from its manufacture through its transport, and then its implementation.

As a general rule, when the temperature measured on the site is below -5 °C, placing concrete is not recommended.

Between -5 °C and + 5 °C, it can only be done with efficient means to prevent the damaging effects of cold.

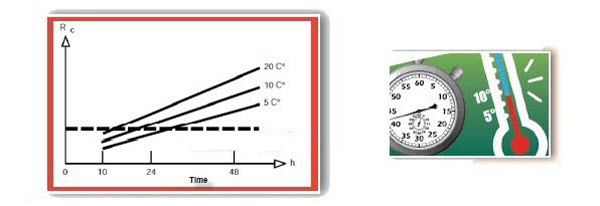

Stripping time limit as a function of temperature

Consequences of the drop in temperature:

On concrete, the drop in temperature within a range that does not reach freezing slows down the exothermic hydration reactions of the cement and we will have:

- A delay in taking

- An extension of the curing time

- An increase in bleeding

- A risk of freezing

- Drop in mechanical resistance

SARL SAPCI has put its experiences by offering its customers an accelerated concrete, a concrete that meets quality requirements and allows pouring in cold weather.

Benefits:

Accelerated concrete is beneficial for:

- Faster concreting in cold weather, allows work to be carried out in unfavourable temperature conditions (between 5 °C and 10 °C).

- Faster commissioning

- Accelerate the setting of the concrete in order to increase the formwork rotations

- Better management of equipment and people

- Catch up on the worksite delay

- Get ahead of the schedule

- Remove form faster

- Ensure concrete setting in cold weather

- Reduction of the cost of labor